Modeling Syngas Production from Methane Reforming Reactors (Data Analytics)

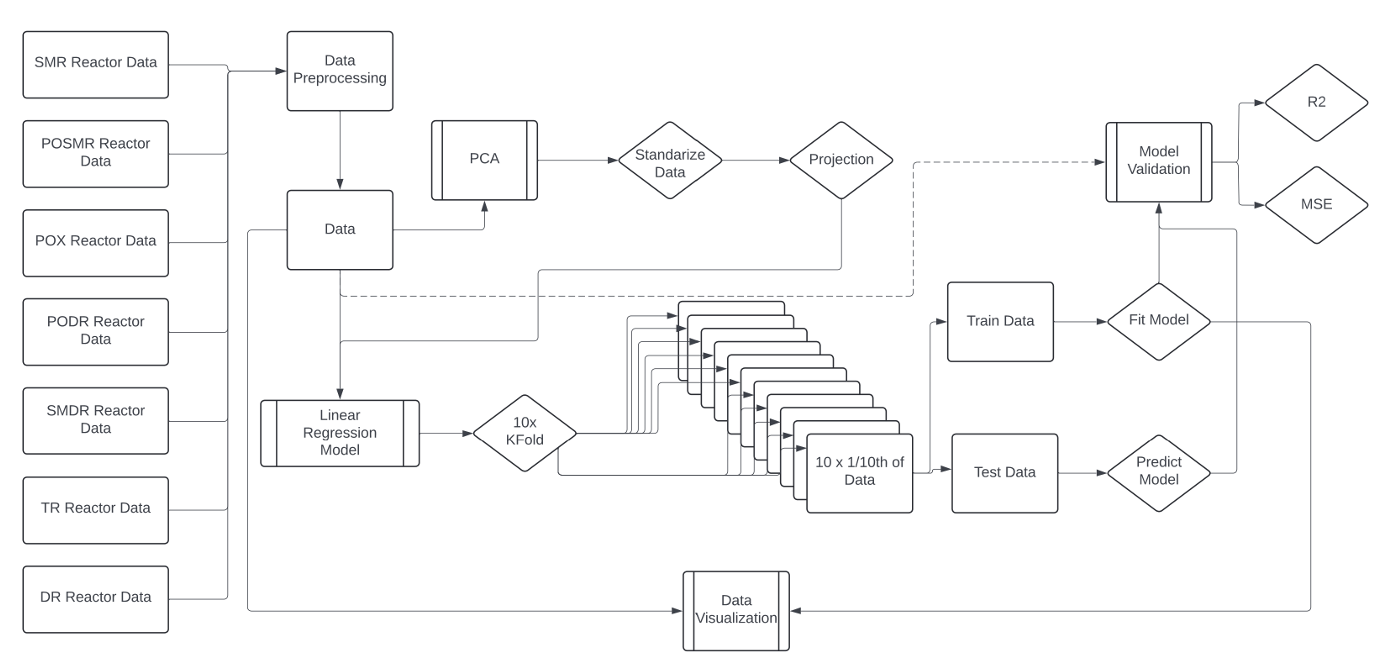

This project focuses on modeling syngas production by analyzing pre-ASPEN-simulated data from various methane reforming reactors. By employing both analytical and numerical techniques, the modeling provides a comprehensive understanding of how key variables (such as reactor settings, feed composition, temperature, etc.) impact syngas production.

Techniques Used: Linear Regression, Non-linear Regression, PCA, KFold, Data Visualization, Neural Network

Graphene Separator for Enhanced Li-Metal Battery Performance (Research)

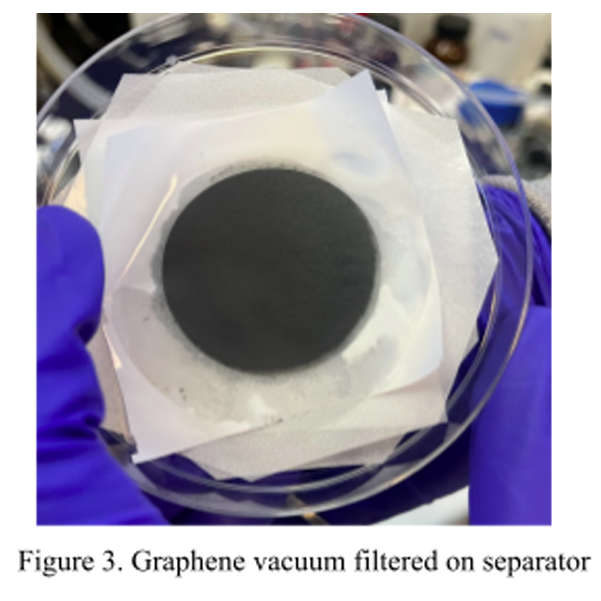

In this project, we developed a graphene separator to assess its effectiveness in inhibiting dendrite formation and enhancing the performance of conventional Li-metal batteries. We evaluated efficiency and capacity to identify the optimal graphene separator thickness.

Techniques Used: Anodic Exfoliation, Assembled coin cell, Graphene characterization (XPS and Ramanspectroscopy), Charge/Discharge profile and Coulombic efficiency

Graphene Oxide-Enhanced Li-ion Battery Performance (Research)

We developed a coin-type Li-ion battery with a graphene oxide electrode to enhance current industrial battery performance in charge/discharge rate and energy storage. We also assessed battery performance through cyclic voltammogram and charge/discharge profiles.

Techniques Used: Developed Slurry, Pasted with Dr. Blade, Constructed Coin Cell, Analysis of Data (CV and Charge/Discharge profiles)

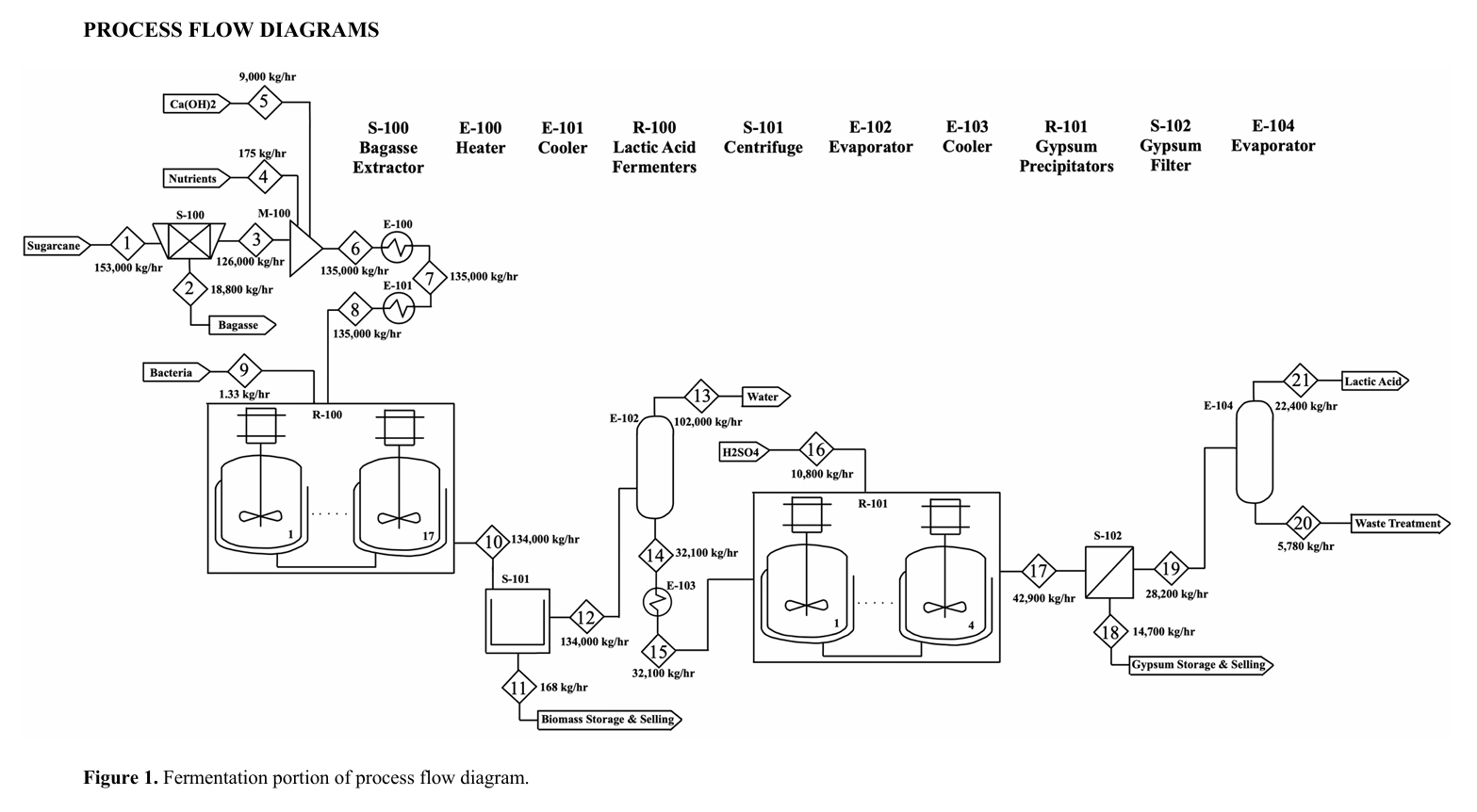

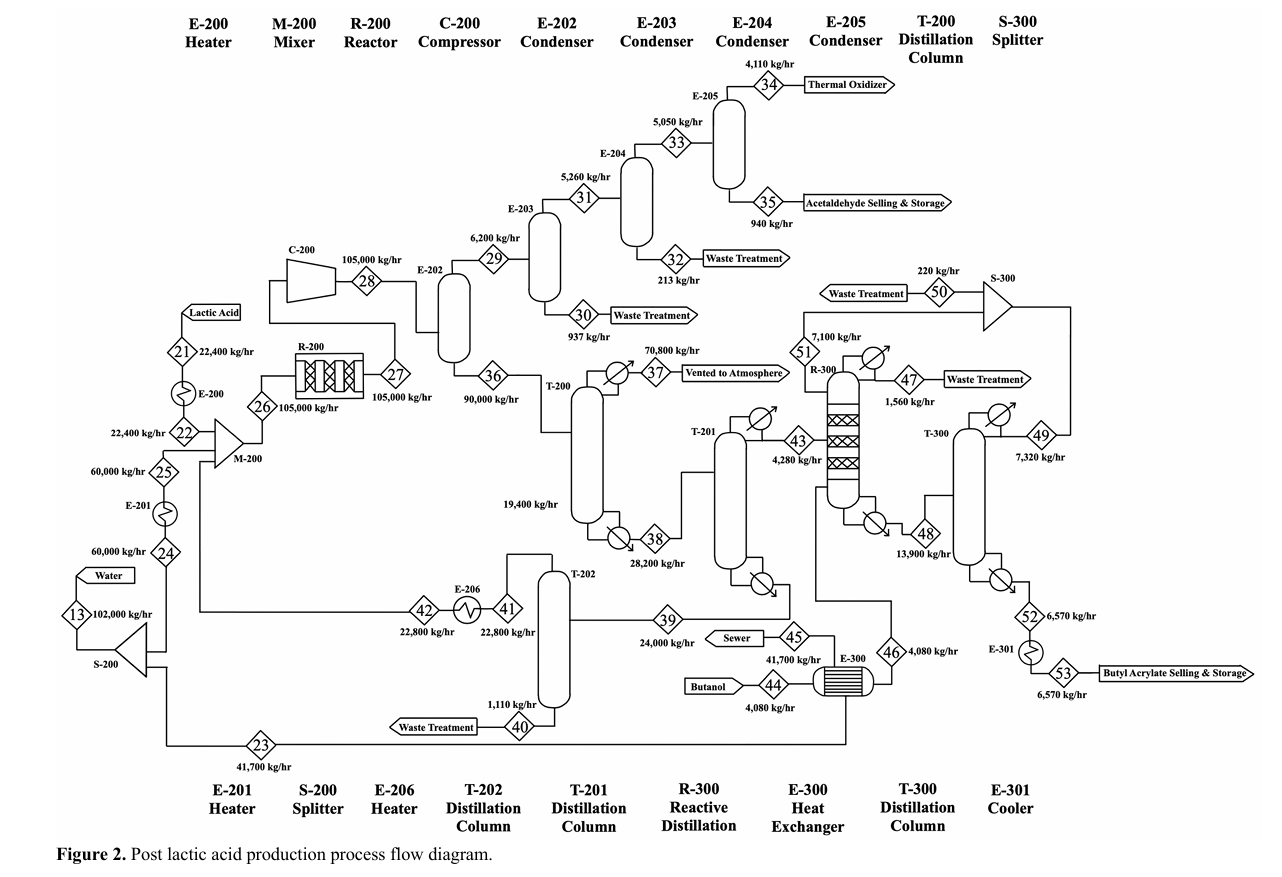

Sugarcane-Based Butyl Acrylate Production (Capstone)

For our capstone project, BASF, our sponsor, was seeking for a more sustainable approach to produce chemicals for their customers. Here, we explored the conversion of sugarcane into butyl acrylate. Since this process is still under development, it required extensive research. We focused on identifying the right kinetic model to simulate the process, as well as determining the optimal number of fermenters and precipitators. The process was optimized by considering selectivity, conversion, and yield, all while aiming to maintain a low product carbon footprint (PCF) and minimize total cost. Additionally, we assessed the efficiency of the process using the Thiele modulus.

Techniques Used: Efficiency (Selectivity, Conversion, Yield, Thiele Modulus), PCF, Heat integration, Economics, Design of Process.

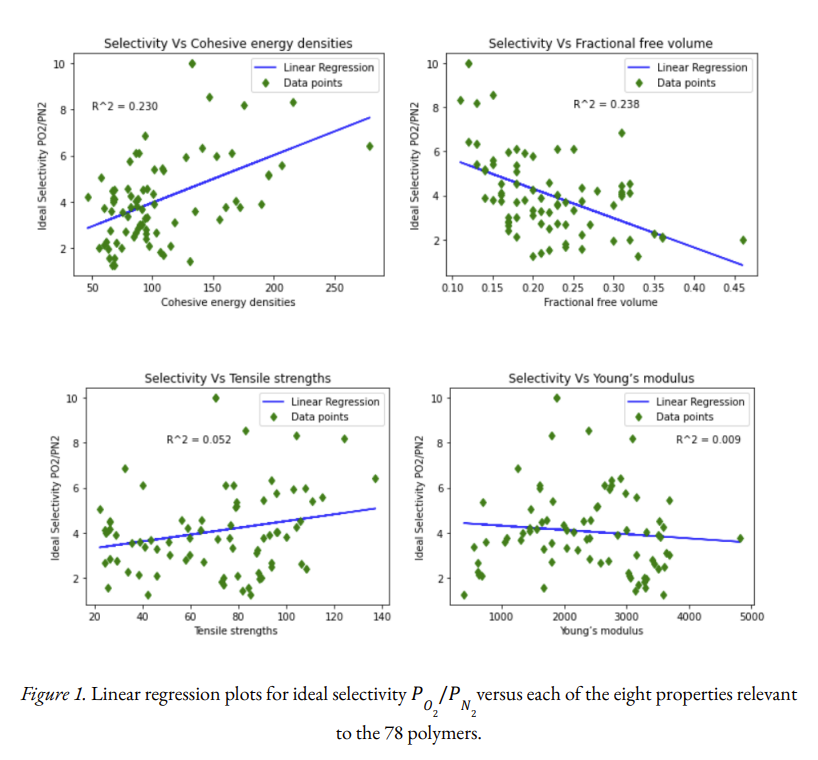

Machine learning for Polymer Selectivity and Solubility

We analyzed gas permeability data in polymers, employing Scikit-learn for linear regression. Additionally, we used a decision tree model (classification) to predict polymer solubility based on experimental conditions, polymer, and solvent properties.

Techniques: Linear Regression, Classification, Confusion Matrix, and F1 Scores

Heat Transfer Analysis in Aluminum and Nylon

Using an aluminum and nylon ball, we assessed heat transfer coefficients for heating and cooling objects via free and forced convection, alongside estimating the thermal conductivity of the material.

Utilized: Heisler Charts and Heat Transfer equations.

Fluid Dynamics: Pump Curve and Flow Analysis

Using water flowing through a hose and valve, we conducted a detailed analysis of pump curves, flow rates, and friction coefficients under diverse conditions (position, time, split flow, and diameter). Additionally, we compared volumetric flow rates and assessed their impact on efficiency.

Equations used: Bernoulli’s, Energy Balance, and Head Loss